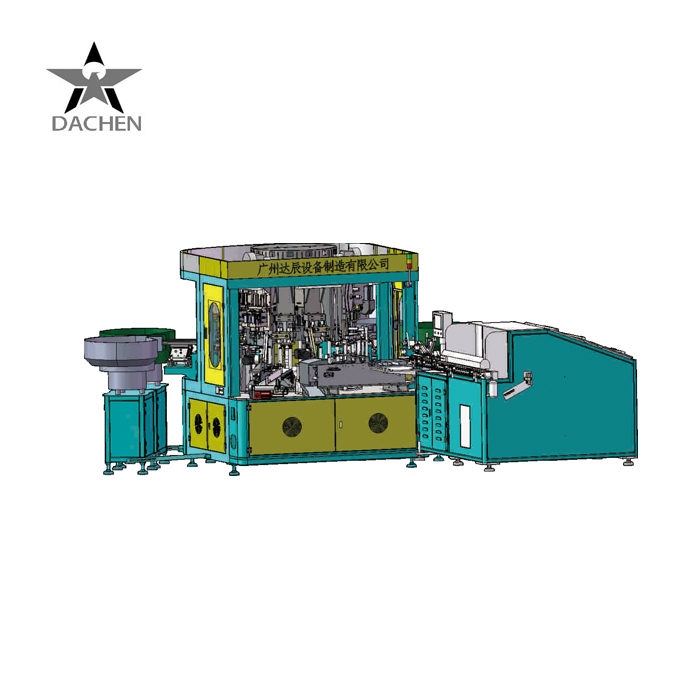

DCH-12 Multifunctional Assembly Capping Machine(Vertical Double-branch)

The Multifunctional Cosmetic Capping Machine is a state-of-the-art solution designed for efficient and precise capping of various types of cosmetic packaging. Built to meet the needs of modern cosmetic manufacturers, this machine offers flexibility, speed, and reliability, making it an ideal choice for automating the capping process for a wide range of products.

The Multifunctional Cosmetic Capping Machine is a state-of-the-art solution designed for efficient and precise capping of various types of cosmetic packaging. Built to meet the needs of modern cosmetic manufacturers, this machine offers flexibility, speed, and reliability, making it an ideal choice for automating the capping process for a wide range of products.

|

Voltage |

220V/50HZ |

|

Power |

4.1KW |

|

Production Efficiency |

60-80PCS/MIN |

|

Tube Diameter |

Φ16-60MM |

|

Tube Length |

40-230MM |

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service