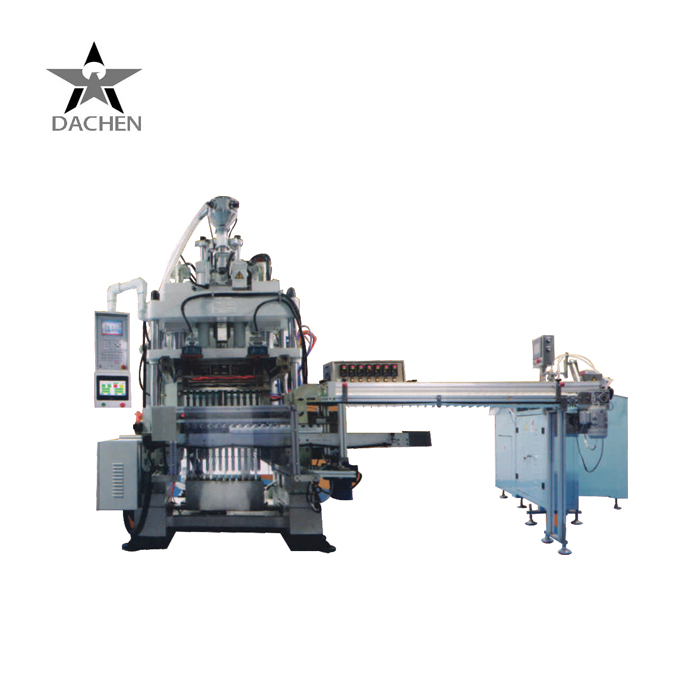

DCH-12 Automatic Turnover Injection Machine

All the bearings and cylinders used for the equipment are imported;The equipment runs stable and operates humanely;It is convenient and quick to change the mould;Compared with the traditional equipment, the heading machine can achieve full automation, safe and efficient production, including automatic tube loading, automatic tube intubation, automatic extubation and automatic material feeding;The appearance of the product is beautiful, and the shoulder teeth are firmly fused with the tube body.No nozzle waste.

The Cosmetic Bottle Injection Head Equipment is a specialized machine designed for the injection molding process of cosmetic bottles. This equipment is used to create high-quality, precise bottle heads that are essential for packaging various cosmetic products, including skincare, makeup, haircare, and personal care items. Engineered for efficiency and precision, this equipment ensures the production of sturdy, aesthetically pleasing bottle heads that meet the cosmetic industry's high standards.

|

Power Supply |

380V/50HZ |

|

Power |

14.6KW |

|

Tube Diameter |

Ø19-50mm |

|

Tube Length |

50-230mm |

|

Productivity |

50-60 pcs/min |

|

Dimensions |

4600*2500*2800mm |

|

Weight |

3000kg |

Key Features:

•Precise Injection Molding: Uses advanced injection molding technology to produce uniform and consistent bottle heads with high accuracy, ideal for a variety of cosmetic formulations.

•Versatile Design: Capable of producing injection heads for various cosmetic bottle types, including pump heads, spray nozzles, droppers, and standard bottle caps.

•High-Speed Production: Offers fast production cycles to meet the demands of high-volume production lines while maintaining high quality and precision.

•Customizable Injection Heads: Adjustable molding parameters to accommodate different bottle designs and sizes, providing flexibility for a wide range of cosmetic products.

•Durable Materials: Designed for use with a variety of materials, such as PET, PP, and ABS, ensuring long-lasting, reliable, and safe packaging for cosmetic products.

•Automated Process: Fully automated or semi-automated versions available, reducing manual labor and enhancing production efficiency.

•Hygienic and Safe: Constructed with stainless steel and food-grade materials to meet GMP and FDA standards, ensuring the highest hygiene and safety during production.

•User-Friendly Interface: Features an intuitive control panel with programmable settings for easy operation and setup, reducing downtime and improving production flexibility.

Applications:

•Skincare Products: Pump and spray heads for serums, lotions, moisturizers, and creams

•Haircare Products: Spray pumps and dispensing heads for shampoos, conditioners, and styling products

•Makeup Products: Applicators and droppers for foundations, face serums, and oils

•Personal Care Items: Bottles for body washes, shower gels, and deodorants

Benefits:

•Increased Production Efficiency: High-speed operation ensures rapid production of bottle heads without compromising quality.

•Improved Product Quality: Precise injection molding results in well-formed, durable, and leak-proof bottle heads, ensuring product integrity.

•Cost Savings: Reduces material waste and manual labor, improving overall cost-effectiveness in production.

•Enhanced Flexibility: Supports customization to accommodate different bottle types, shapes, and sizes, making it ideal for various cosmetic products.

•Compliance with Industry Standards: Meets hygiene and safety regulations, ensuring products are manufactured in a clean and controlled environment.

The Cosmetic Bottle Injection Head Equipment is a critical tool for manufacturers looking to streamline their packaging process while maintaining high-quality standards. Whether for skincare, haircare, or makeup products, this equipment provides the precision, speed, and reliability needed for producing top-tier cosmetic packaging.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service