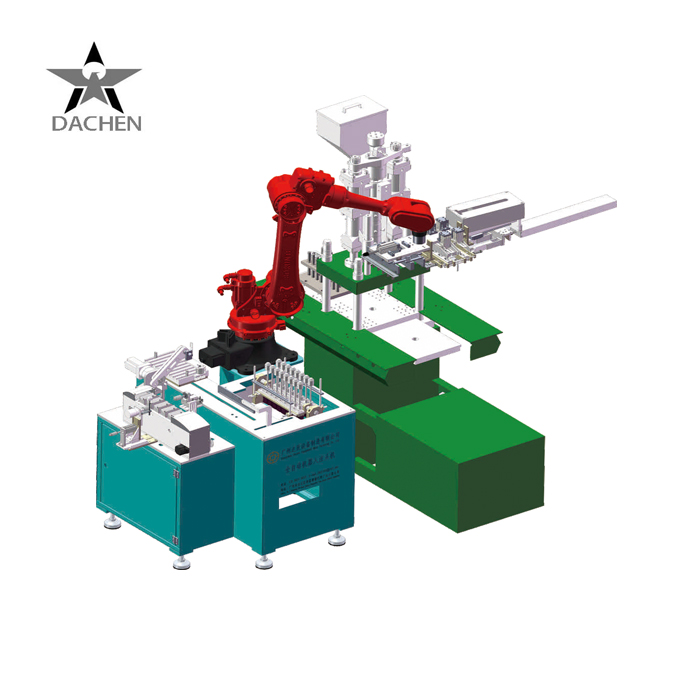

DCH-51 Alignment Injection Head Robot

Automatic Heading Machine Description:

Can produce positions like Ultra flat tube , round tube

mold developing cost is low and Save labor

All the bearings and cylinders used for the equipment are imported;

The equipment runs stable and operates by robot

It is convenient and quick to change the mold;

Compared with the traditional equipment, the heading machine can achieve full

automation, safe and efficient production, including automatic tube loading,

automatic tube intubation, automatic extubation and automatic material feeding;

The appearance of the product is beautiful, and the shoulder teeth are firmly

fused with the tube body. No nozzle waste.

Automatic Heading Machine Description:

Can produce positions like Ultra flat tube , round tube

mold developing cost is low and Save labor

All the bearings and cylinders used for the equipment are imported;

The equipment runs stable and operates by robot

It is convenient and quick to change the mold;

Compared with the traditional equipment, the heading machine can achieve full

automation, safe and efficient production, including automatic tube loading,

automatic tube intubation, automatic extubation and automatic material feeding;

The appearance of the product is beautiful, and the shoulder teeth are firmly

fused with the tube body. No nozzle waste.

|

Voltage |

380V/50Hz |

|

Power |

3.6Kw |

|

Production

efficiency |

60-80

PCS/min |

|

tube

diameter |

13-60mm |

|

tube

length |

40-230mm |

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service