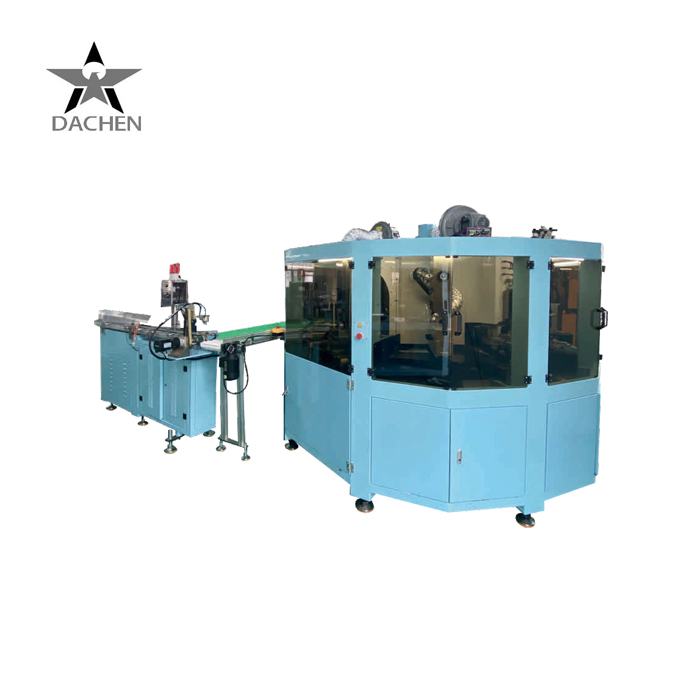

DCH-21 Multicolor Screen Printing Equipment

Cosmetic Pack Multicolor Screen Printing

Machine

Full plate positioning accuracy

Independent glazing , high efficiency

optional LED mercury

All the bearings and cylinders used for the

equipment are imported.

The photoelectric induction is used to

automatically calibrate and locate the target quickly and accurately.

The integral screw adjusting mode is

adopted, which makes it convenient and quick to adjust the machine and replace

the tooling.

Compared with the traditional equipment,

the three color printing machine can

achieve full automation, safe and efficient production, including automatic

tube loading, automatic tube intubation, automatic extubation and automatic

material feeding。

The Cosmetic Pack Multicolor Screen

Printing Machine is a high-performance solution designed for precise and

vibrant printing on cosmetic packaging. Engineered for efficiency and superior

print quality, this machine caters to the aesthetic and branding needs of the

cosmetic industry, ensuring premium and eye-catching designs for your products.

Cosmetic Pack Multicolor Screen Printing Machine

Full plate positioning accuracy

Independent glazing , high efficiency

optional LED mercury

All the bearings and cylinders used for the equipment are imported.

The photoelectric induction is used to automatically calibrate and locate the target quickly and accurately.

The integral screw adjusting mode is adopted, which makes it convenient and quick to adjust the machine and replace the tooling.

Compared with the traditional equipment, the three color printing machine can achieve full automation, safe and efficient production, including automatic tube loading, automatic tube intubation, automatic extubation and automatic material feeding。

The Cosmetic Pack Multicolor Screen Printing Machine is a high-performance solution designed for precise and vibrant printing on cosmetic packaging. Engineered for efficiency and superior print quality, this machine caters to the aesthetic and branding needs of the cosmetic industry, ensuring premium and eye-catching designs for your products.

|

Power Supply |

380V/50HZ |

|

Power |

28 KW |

|

Tube Diameter |

Ø16-60mm |

|

Tube Length |

40-230mm |

|

Multi color + glazing |

Three color |

|

Multi color |

Three color |

|

Productivity |

60 pcs/min |

Key Features:

Multicolor Printing: Supports intricate and vibrant designs with multiple color layers for enhanced visual appeal.

Wide Application Range: Suitable for printing on bottles, tubes, jars, caps, and other curved or flat surfaces.

High Precision: Advanced registration system ensures accurate alignment for seamless and professional results.

Durable Printing: Uses high-quality inks and curing systems to provide long-lasting, smudge-proof prints.

Customizable Options: Adjustable settings to accommodate various shapes, materials (plastic, glass, metal), and sizes of cosmetic packaging.

Efficient Operation: Fully automated or semi-automated models available for high-speed production.

User-Friendly Interface: Intuitive controls and programmable settings for quick adjustments and job changeovers.

Eco-Friendly Design: Compatible with low-VOC and environmentally safe printing inks.

Applications:

Skincare Packaging: Cream jars, serum bottles, and lotion tubes

Makeup Packaging: Lipstick tubes, compact cases, and foundation bottles

Haircare Packaging: Shampoo and conditioner bottles

Fragrance Bottles: Glass and plastic perfume bottles

Advantages:

Delivers premium-quality prints that enhance brand value and shelf appeal

Supports complex and detailed artwork, including logos, patterns, and text

Increases production efficiency with high-speed printing capabilities

Reduces printing defects with precise and reliable operation

Enhances flexibility with support for a variety of packaging shapes and materials

Our Cosmetic Pack Multicolor Screen Printing Machine is the ultimate choice for manufacturers seeking to elevate their packaging aesthetics and brand identity. Contact us today to learn how this machine can transform your packaging into a work of art while streamlining your production process.

Let me know if you’d like to adjust the tone, add technical specifications, or focus on specific features!

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service