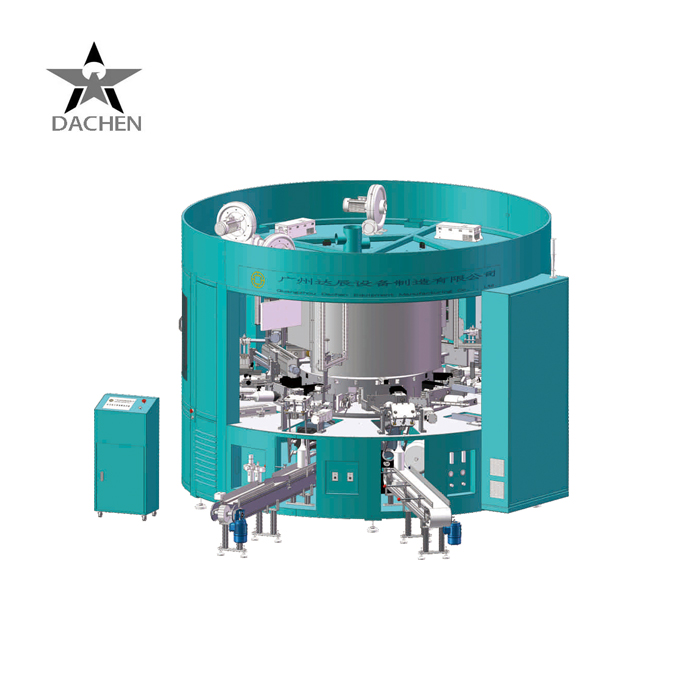

DCH-22 Special-shaped Bottle Screen Printing Machine

Automatic Bottle Six Color Printing Machine descriptionPET bottle, glass bottle curved surfaceCone screen printing accurate and efficient positioningAll the bearings and cylinders used for the equipment are imported.The photoelectric induction is used to automatically calibrate and locate the target quickly and accurately.The integral screw adjusting mode is adopted, which makes it convenient and quick to adjust the machine and replace the tooling.A cosmetic special-shaped bottle screen printing machine is designed specifically for printing on uniquely shaped cosmetic bottles, such as those used for lotions, serums, oils, and other personal care products. These machines are engineered to handle non-standard shapes that may present challenges for traditional printing methods. Below is a detailed description of this equipment:OverviewThe special-shaped bottle screen printing machine employs the screen printing technique to achieve high-quality and precise prints on bottles with complex geometries. This allows manufacturers in the cosmetics industry to enhance product aesthetics and branding while ensuring durability.

Automatic Bottle Six Color Printing Machine description

PET bottle, glass bottle curved surface

Cone screen printing accurate and efficient positioning

All the bearings and cylinders used for the equipment are imported.

The photoelectric induction is used to automatically calibrate and locate the target quickly and accurately.

The integral screw adjusting mode is adopted, which makes it convenient and quick to adjust the machine and replace the tooling.

A cosmetic special-shaped bottle screen printing machine is designed specifically for printing on uniquely shaped cosmetic bottles, such as those used for lotions, serums, oils, and other personal care products. These machines are engineered to handle non-standard shapes that may present challenges for traditional printing methods. Below is a detailed description of this equipment:

Overview

The special-shaped bottle screen printing machine employs the screen printing technique to achieve high-quality and precise prints on bottles with complex geometries. This allows manufacturers in the cosmetics industry to enhance product aesthetics and branding while ensuring durability.

|

Power Supply |

380V/50HZ |

|

Power |

43 KW |

|

Tube Diameter |

Ø16-100mm |

|

Tube Length |

40-230mm |

|

Multi color + glazing |

Six color |

|

Multi color |

Three color + curved corner printing |

|

Productivity |

60 pcs/min |

Specialized Printing Capability:

Designed specifically to accommodate various non-standard or intricate bottle shapes (e.g., curved surfaces, irregular contours).

Adjustable fixtures or clamps secure the bottles during the printing process, ensuring stability.

Multicolor Printing Options:

Capable of applying multiple colors in one print cycle through separate screens.

Incorporates advanced registration systems for precise alignment of each color layer.

High Precision and Quality:

Utilizes fine mesh screens that allow for sharp details and vibrant colors.

Supports a variety of ink types including solvent-based, UV-curable inks that adhere well to different materials.

User-Friendly Controls:

Equipped with digital control panels or touchscreens that allow operators to easily set parameters such as print speed, pressure, and ink flow.

Programmable settings enable quick adjustments based on specific production runs.

Versatile Substrate Compatibility:

Suitable for different materials like glass, PET plastic, PVC plastic, and even metal.

Can handle various textures (smooth vs textured) while maintaining print integrity.

Automated Functions:

Many models feature automatic loading/unloading systems which streamline production workflow by minimizing manual handling.

Integration with conveyor belts enhances efficiency by allowing continuous operation.

Ink Curing Solutions:

Offers options such as UV curing lamps or infrared drying systems that rapidly cure inks post-printing.

Offers options such as UV curing lamps or infrared drying systems that rapidly cure inks post-printing.

Ensures quick turnaround times suited for high-volume production environments without compromising quality.

Eco-Friendly Practices:

Some machines utilize eco-friendly inks compliant with safety regulations relevant in the cosmetics industry—important due to consumer safety concerns regarding chemical exposure.

Maintenance Convenience:

Designed for ease of maintenance; includes features such as self-cleaning mechanisms or removable components facilitating prompt servicing between jobs.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service