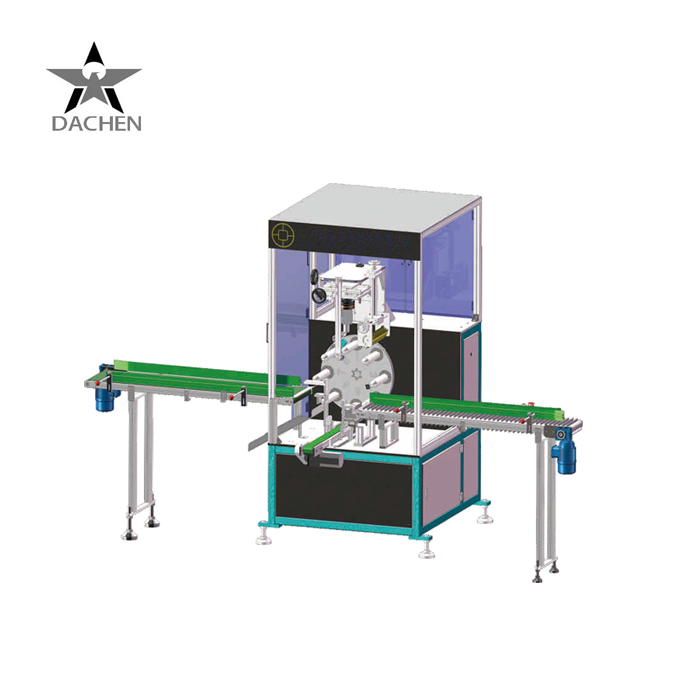

DCH-41 Quality Inspection Machine

The Cosmetic Quality Check Machine is a high-precision system designed to ensure that cosmetic products meet the highest standards of quality and consistency. This machine provides an automated solution for inspecting cosmetic products during various stages of production, ensuring defect-free packaging, labeling, filling, and other key quality parameters.

|

Power Supply |

220V/50HZ |

|

Power |

1.5KW |

|

Appearance process defect |

Outgoing tube |

|

Stain defect |

Outlet tube |

|

Productivity |

60 pcs/min |

Key Features:

• Comprehensive Inspection: Capable of checking a wide range of quality parameters, including fill levels, seal integrity, label placement, cap tightness, and visual defects like scratches or discoloration.

• High Accuracy: Uses advanced sensors, cameras, and vision systems for precise and reliable inspections, ensuring consistent product quality.

• Automated Operation: Reduces human error and speeds up the quality control process with fully automated inspection cycles.

• Real-Time Monitoring: Provides instant feedback and reports on the production line to alert operators about any quality issues or defects.

• Non-Destructive Testing: Inspects products without damaging them, allowing for further processing if necessary.

• Customizable Settings: Adjustable inspection parameters to accommodate different product types, sizes, and packaging designs.

• Easy Integration: Compatible with existing production lines, allowing for seamless integration into new or ongoing production processes.

• User-Friendly Interface: Equipped with an intuitive touchscreen control panel for easy operation and monitoring.

Applications:

• Skincare Products: Checking for proper fill levels, labels, seals, and packaging integrity for jars, bottles, and tubes

• Makeup Products: Ensuring the correct quantity, labeling accuracy, and cap sealing for lipstick tubes, foundations, and other cosmetics

• Haircare Products: Verifying fill volume, capping, and labeling for shampoo, conditioner, and styling products

• Personal Care Items: Ensuring the quality of packaging for items like deodorants, lotions, and balms

Benefits:

• Improves Product Consistency: Ensures that every unit leaving the production line meets strict quality standards.

• Enhances Operational Efficiency: Automates manual inspection tasks, reducing labor costs and speeding up the production process.

• Reduces Waste: Detects defective products before they reach customers, minimizing returns and improving customer satisfaction.

• Boosts Brand Reputation: Ensures the high quality of cosmetic products, enhancing brand credibility and consumer trust.

• Real-Time Data: Provides valuable insights through real-time data collection and reporting, enabling better decision-making and quality management.

The Cosmetic Quality Check Machine is an essential investment for cosmetic manufacturers focused on delivering high-quality products to the market. By automating quality control, this machine ensures that every product meets the required standards of excellence, maintaining your brand's reputation and reducing costly production errors.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service