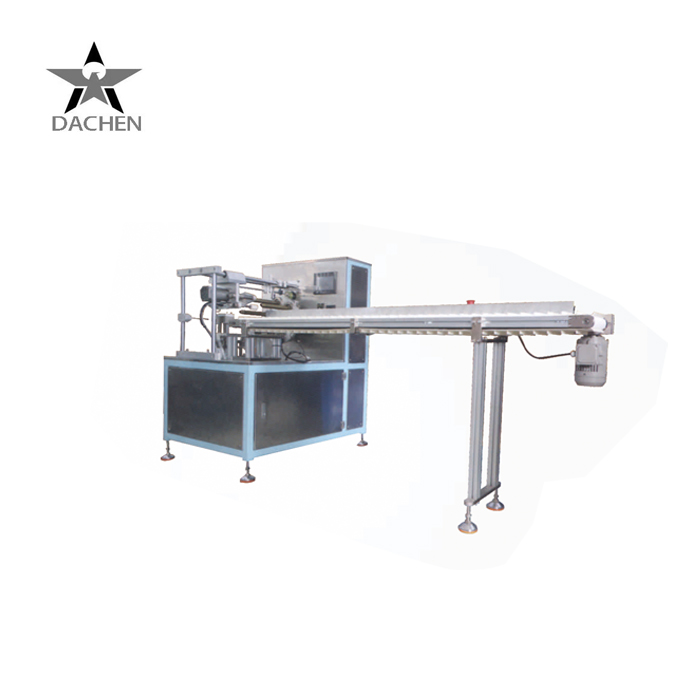

Soft Tube Bottle Punching and Pipe Cutting Machine

Technical parameterVoltage:220V/50HzPower: 1.5kw Production efficiency: 60-80 PCS/minPipe cutting length error: ≤0.1Flatness error difference of pipe cutting: ≤0.1mmProducible pipe diameter: p16-100mmProducible pipe length: 40-300mm

Technical parameter

Voltage:220V/50Hz

Power: 1.5kw

Production efficiency: 60-80 PCS/min

Pipe cutting length error: ≤0.1

Flatness error difference of pipe cutting: ≤0.1mm

Producible pipe diameter: p16-100mm

Producible pipe length: 40-300mm

The soft tube bottle punching and pipe cutting machine is a specialized piece of equipment designed for the cosmetic, pharmaceutical, and food industries. It efficiently performs two primary functions: creating openings or punch holes in soft plastic tubes (such as squeeze tubes) and cutting plastic pipes or tubes to specified lengths. This machine is instrumental in streamlining production processes while ensuring precision and quality control.

Key Features

Dual Functionality:

Combines both punching and cutting capabilities, allowing manufacturers to perform two essential operations in one seamless workflow.

Designed for flexibility to accommodate different types of soft tubes and pipes.

Precision Cutting & Punching:

Utilizes advanced blade technology for clean cuts without burrs, minimizing waste material.

Equipped with adjustable punch settings facilitating various hole sizes according to product specifications.

User-Friendly Controls:

Features an intuitive control panel with digital displays for easy operation.

Simple setup process allows operators to input precise measurements quickly for each production run.

High Speed & Efficiency:

Capable of processing a significant number of units per hour based on tube size and complexity.

Automated functions reduce manual labor while increasing overall productivity.

Durable Construction:

– Built with high-quality materials that withstand continuous use in demanding production environments.

– Components are designed for easy access which simplifies maintenance routines.

Safety Mechanisms:

– Includes emergency stop features, safety guards around moving parts, and sensors that prevent operation when components are not correctly positioned.

– Compliance with industry safety standards ensures operator protection during use.

Adjustable Settings & Versatility:

– Customizable settings cater to various tube diameters, wall thicknesses, tube materials (such as polyethylene or polypropylene), enhancing compatibility across products.

– Can handle both standard-sized containers as well as specialized custom designs with ease.

Waste Reduction Features:

– Incorporates systems that collect trimmings from the cutting process reducing material waste significantly—an essential aspect of sustainable manufacturing practices.

Data Logging Capabilities:

– Integrated monitoring systems track performance metrics like throughput rates, operational times, maintenance reminders etc., promoting efficiency improvements over time.

Applications

Manufacturing of cosmetic packaging (creams/lotions)

Pharmaceutical containers (ointment/treatment gels)

Food industry applications (sauces/dressings)

Personal care products (toothpaste/shampoos)

Conclusion

The soft tube bottle punching and pipe cutting machine plays a crucial role in modern manufacturing lines by providing accuracy in handling flexible packaging solutions such as soft tubes while optimizing operational efficiency through automation features . Its dual functionality not only saves valuable floor space but also minimizes labor costs associated with separate processes . With robust construction , user-friendly controls ,and adherence to safety protocols , businesses can enhance their productivity levels significantly thereby meeting market demands effectively!

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service