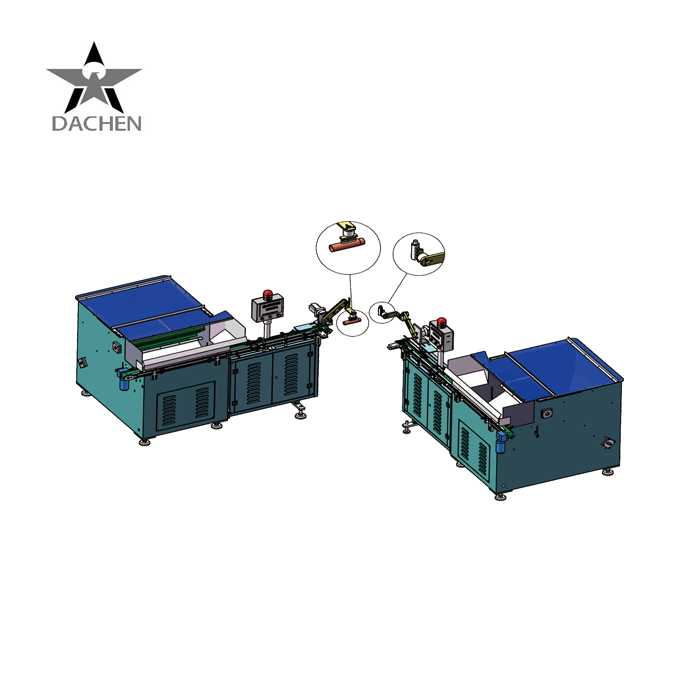

DCH-53 Fully automatic bottle sorting equipment

Voltage:220V/50Hz Power: 1.5kwProduction efficiency: 60-120PCS/min Diameter of producible tube:16-100mm Length of producible bottle:1040-300mm

Voltage:220V/50Hz

Power: 1.5kw

Production efficiency: 60-120PCS/min

Diameter of producible tube:16-100mm

Length of producible bottle:1040-300mm

Fully Automatic Bottle Sorting Equipment

The fully automatic bottle sorting equipment is designed to sort bottles in one direction in a manufacturing environment. And there is an orderly entry conveyor line. The equipment is designed to improve efficiency and precision, minimize manual labor while maximizing production, ensuring that bottles are sorted according to various criteria such as size, shape, color or label type.

High-Speed Sorting:

Capable of processing thousands of bottles per hour through advanced algorithms and rapid conveyor systems.

Optimized for minimal downtime with quick changeover capabilities between different bottle types.

Advanced Sensor Technology:

Utilizes a combination of optical sensors (cameras), laser scanners, and weight detectors to accurately identify each bottle's characteristics.

Real-time data processing enables immediate adjustments based on detected anomalies or changes in production batches.

User-Friendly Interface:

Equipped with a touchscreen control panel that allows operators to easily program sorting parameters and monitor system performance.

Intuitive software provides step-by-step guidance for setup and troubleshooting.

Customizable Sorting Criteria:

Flexibility to sort based on multiple attributes including:

Bottle size (height/diameter)

Shape (round/square/irregular)

Color recognition

Label presence or absence

– Material type (glass/plastic)

Robust Construction:

– Built from durable materials designed to withstand the rigors of continuous operation within harsh industrial environments.

– Engineered for easy cleaning to maintain hygiene standards essential in food & beverage or cosmetic industries.

Integration Capabilities:

– Designed to seamlessly integrate with existing production lines or conveyor systems for streamlined operations.

– Compatibility with other automated equipment such as filling machines and packaging lines enhances overall productivity.

Automatic Jam Detection & Recovery System:

– Smart sensors detect bottlenecks or jams within the system; automated recovery procedures minimize downtime without manual intervention.

– Alerts operators promptly via visual/audible signals when maintenance is required.

Data Logging & Reporting Functions:

– Built-in data management features capture operational metrics like throughput rates, error rates, and maintenance schedules.

– Export functionality supports compliance reporting requirements through formats such as CSV/PDFs for quality assurance records.

Energy-Efficient Design:

– Incorporates energy-saving technologies that reduce electricity consumption during idle times without compromising performance levels during operation.

Applications

Beverage industry (water bottles, soft drinks)

Food packaging (jars/cans)

Cosmetic containers

Pharmaceutical products

Household goods

Conclusion

Fully automatic bottle sorting equipment represents a significant leap forward in optimizing manufacturing processes across various industries by enhancing speed while reducing labor costs associated with manual sorting methods., Its advanced sensor technology coupled with user-friendly interfaces ensures reliability even when handling diverse product ranges.. By integrating this equipment into their operations companies can achieve higher accuracy ,efficiency ,and overall productivity—ultimately leading them toward improved profitability!

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service