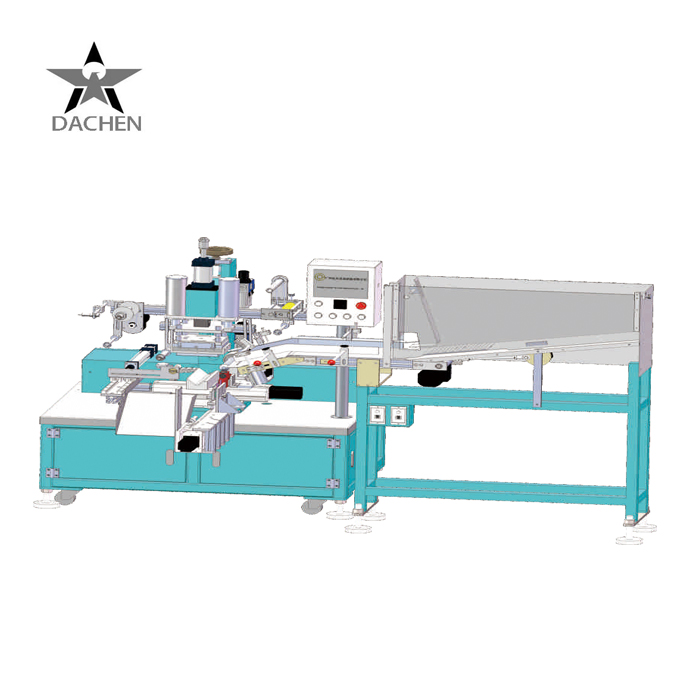

DCH-54 Cosmetic bottle Bronzing Machine

Cosmetic Bottles Bronzing Machine

A cosmetic bottles bronzing machine is a

specialized piece of equipment designed to apply a metallic or bronzed finish

to cosmetic packaging. This machine enhances the aesthetic appeal of bottles,

jars, and other containers, making them stand out on store shelves. By using

advanced techniques such as heat transfer printing or foiling, the bronzing

machine provides a premium look that reflects quality and luxury.

Cosmetic Bottles Bronzing Machine

A cosmetic bottles bronzing machine is a

specialized piece of equipment designed to apply a metallic or bronzed finish

to cosmetic packaging. This machine enhances the aesthetic appeal of bottles,

jars, and other containers, making them stand out on store shelves. By using

advanced techniques such as heat transfer printing or foiling, the bronzing

machine provides a premium look that reflects quality and luxury.

|

Voltage |

220V/50Hz |

|

Power |

1.8Kw |

|

Production efficiency |

28-32 PCS/min |

|

tube diameter |

13-60mm |

|

tube length |

40-230mm |

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service