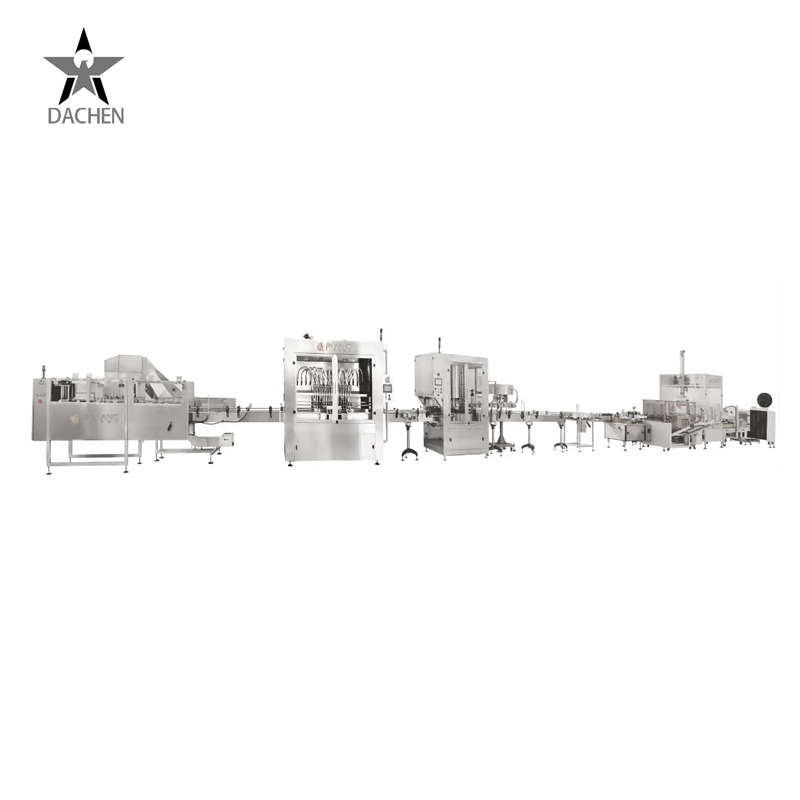

Fully Automatic Cosmetic Equipment Product Line

Fully Automatic Cosmetic Equipment Product Line Solution Description

The fully automatic cosmetic equipment product line is a state-of-the-art manufacturing solution designed for the efficient and precise production of a wide range of cosmetic products. This solution is tailored to meet the needs of modern cosmetics manufacturers, providing high-speed production, consistent product quality, and reduced labor costs. The system integrates advanced automation technologies, modular components, and intelligent controls to streamline every step of the production process.

The fully automatic cosmetic equipment product line is a state-of-the-art manufacturing solution designed for the efficient and precise production of a wide range of cosmetic products. This solution is tailored to meet the needs of modern cosmetics manufacturers, providing high-speed production, consistent product quality, and reduced labor costs. The system integrates advanced automation technologies, modular components, and intelligent controls to streamline every step of the production process.

The product line can be customized based on

the type of cosmetic product (e.g., creams, lotions, lipsticks, foundations, or

mascaras).

Flexible modules allow for easy upgrades

and adjustments to accommodate new formulations or packaging designs.

High Precision Filling System

Utilizes advanced filling technologies (e.g., volumetric, piston, or peristaltic pump fillers) for accurate and efficient dispensing of products.

Supports various viscosities, from liquid

serums to thick creams.

Multi-functional Packaging Integration

Includes automated bottle or jar feeding, labeling, capping, and sealing.

Compatible with a wide range of packaging

materials, including glass, plastic, and metal containers.

Options for shrink wrapping, tamper-proof

sealing, or customized packaging.

Smart Control System

Equipped with a programmable logic controller (PLC) and a human-machine interface (HMI) for real-time monitoring and control.

Enables precise adjustments to filling,

capping, labeling, and other parameters.

Includes automated fault detection and

troubleshooting.

Advanced Quality Control

Inline quality inspection systems for checking filling accuracy, seal integrity, and labeling precision.

Can include vision systems to detect

packaging defects or ensure proper alignment of labels.

Energy Efficiency and Sustainability

Supports eco-friendly materials and

practices to align with sustainability goals.

Hygienic Design

Constructed with stainless steel and food-grade materials to meet cosmetic and pharmaceutical production standards.

Easy to clean and maintain, with options

for Clean-In-Place (CIP) systems.

Process Workflow

Raw Material Preparation

Automated mixing and homogenization systems for blending ingredients to desired consistency and texture.

Heating, cooling, and emulsification

options for producing creams, gels, or other formulations.

Filling and Dispensing

Containers are automatically fed into the system, positioned, and filled with precise volumes of product.

Filling options include single or

multi-head filling to increase throughput.

Sealing and Capping

Fully automated sealing for jars, bottles, or tubes.

Screw capping, snap capping, or crimp

sealing available based on packaging type.

Labeling and Printing

High-speed labeling system applies labels accurately.

Inkjet or laser printing for batch numbers,

expiration dates, or custom branding.

Final Packaging

Automated cartoning, shrink-wrapping, or boxing for secondary packaging.

Integration with palletizing systems for

end-of-line operations.

Applications

The fully automatic cosmetic equipment

product line is suitable for the production of:

Skincare Products: Creams, serums, toners, lotions, and masks.

Makeup: Lipsticks, foundations, mascaras,

and powders.

Haircare: Shampoos, conditioners, and

styling products.

Other Products: Sunscreens, body oils, and

deodorants.

Benefits

High Productivity: Enables mass production

with minimal downtime.

Cost-Effective: Reduces labor costs and

material wastage.

Consistent Quality: Ensures precise

formulation, packaging, and labeling.

Scalability: Easily adaptable to changing

production needs.

Regulatory Compliance: Meets international

cosmetic manufacturing standards (e.g., GMP, ISO).

Customization Options

The solution can be tailored to specific

customer needs, including:

Production capacity and output speed.

Container sizes and shapes.

Integration with existing manufacturing

systems.

Industry-specific requirements (e.g.,

organic cosmetics, pharmaceutical-grade products).

This fully automatic cosmetic equipment

product line solution is ideal for companies seeking to scale production,

enhance product quality, and stay competitive in the fast-growing cosmetics

industry.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service