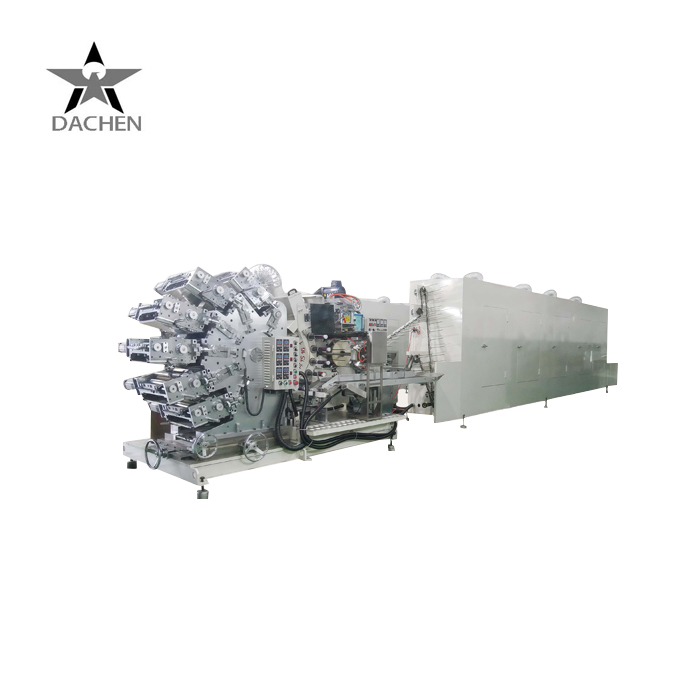

Six-Color Offset Printing Machinery for Cosmetic Tube Packaging

A six-color offset printing machine for cosmetic tube packaging is an advanced system specifically designed to print high-quality designs and branding on cosmetic tubes. This machine uses offset printing technology to apply intricate graphics, text, and patterns onto tubes with exceptional clarity, vibrant colors, and durability. It is widely used in the cosmetic, personal care, and pharmaceutical industries to create visually appealing packaging that enhances product presentation and brand recognition.

Multi-Color Printing Capability

Equipped with six color stations, allowing the simultaneous application of up to six colors.

Compatible with CMYK, Pantone, and metallic inks for custom branding and decorative effects.

High-Quality Offset Printing

Uses advanced offset technology to ensure precise color registration and sharp image resolution.

Provides smooth gradients and fine details, ideal for complex artwork and designs.

360° Tube Printing

Capable of printing on the entire cylindrical surface of the cosmetic tube.

Ensures seamless artwork alignment without visible joints or overlaps.

Material Compatibility

Supports a wide range of cosmetic tube materials, including:

Plastic tubes (PE, PP, PET).

Laminated tubes.

Aluminum tubes.

UV Curing System

Integrated UV curing units immediately dry the ink after printing.

Produces vibrant and durable prints resistant to smudging, fading, and scratches.

Automatic Tube Feeding and Positioning

Fully automated tube loading, feeding, and alignment for precise and efficient operation.

Ensures accurate positioning of the tube for consistent print quality.

Fast Changeover

Quick and easy setup for different tube sizes, designs, and artwork.

Reduces downtime when switching between production batches.

User-Friendly Operation

PLC-based control system with a touchscreen Human-Machine Interface (HMI) for intuitive operation.

Real-time monitoring of printing parameters and fault diagnostics.

Eco-Friendly Design

Uses low-VOC inks and UV curing to minimize environmental impact.

Optimized ink transfer system reduces waste and ensures efficient use of materials.

High-Speed Printing

Capable of printing up to 120 tubes per minute, depending on tube size and design complexity.

Designed for high-volume production with consistent quality.

Production Workflow

Tube Feeding

Empty tubes are automatically loaded and aligned on the machine.

Printing Process

The machine applies up to six colors in a sequential manner using offset printing cylinders.

Precise registration ensures sharp and accurate reproduction of artwork.

UV Curing

UV curing lamps instantly dry the ink, making the tubes ready for immediate handling.

Quality Inspection

Inline inspection systems check for color accuracy, registration, and defects.

Collection

Printed tubes are automatically collected and transferred for further processing (e.g., sealing or capping).

Applications

This machine is ideal for printing on cosmetic tubes used in:

Skincare Products: Creams, lotions, and gels.

Haircare Products: Conditioners, masks, and styling gels.

Personal Care: Toothpaste, sunscreen, and hand cream.

Pharmaceutical Products: Ointments and medicinal creams.

Benefits

Premium Print Quality: Produces vibrant, high-resolution designs that enhance product appeal.

Flexibility: Capable of handling various tube sizes, materials, and artwork requirements.

Efficiency: High-speed operation ensures fast turnaround for large production volumes.

Durability: UV-cured prints are resistant to fading, scratching, and chemical exposure.

Cost-Effectiveness: Reduces material waste and operational downtime, ensuring lower production costs.

Customization Options

Support for special effects such as metallic or pearlescent inks.

Adjustable for different tube diameters (e.g., 13mm to 50mm) and lengths.

Integration with inline quality control or additional printing technologies (e.g., silkscreen or hot stamping).

Conclusion

The six-color offset printing machine for cosmetic tube packaging is an essential tool for manufacturers seeking to create visually striking and durable packaging. Its advanced features, high efficiency, and compatibility with various materials make it an invaluable investment for businesses in the cosmetics and personal care industry. This machine not only enhances the aesthetic appeal of products but also helps strengthen brand identity in competitive markets.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service