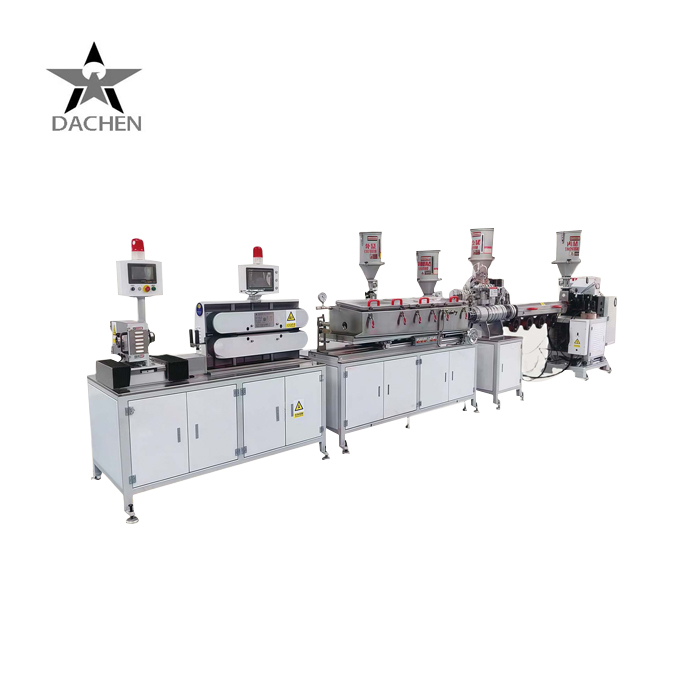

Cosmetic Tube Extruder Equipment

cosmetic tube extruder is a specialized machine used in the manufacturing of cosmetic tubes. These tubes are commonly used for packaging skincare creams, lotions, gels, and other personal care products. The extruder forms the tube body by melting and shaping plastic materials such as polyethylene (PE), polypropylene (PP), or laminated materials into seamless, high-quality cosmetic tubes. The machine ensures precise dimensions, consistent wall thickness, and smooth finishes, making it an essential component of the cosmetic packaging production line.

High-Precision Extrusion

Advanced extrusion technology ensures uniform tube wall thickness and smooth surfaces.

Adjustable settings for tube diameters and lengths to suit various product requirements.

Material Compatibility

Supports various materials, including:

Mono-layer plastics: PE, PP.

Multi-layer plastics: Co-extrusion for added durability and barrier protection.

Laminated materials: Aluminum-plastic composites for superior barrier properties.

Efficient Heating and Cooling Systems

Precision temperature control ensures consistent material melting during extrusion.

Cooling systems solidify the extruded tube quickly for efficient production.

Customization and Versatility

Accommodates a variety of cosmetic tube designs, including cylindrical, oval, and custom shapes.

Can produce tubes with different finishes, such as matte, glossy, or soft-touch surfaces.

Automatic Cutting and Trimming

Integrated cutting and trimming systems ensure precise tube length and smooth edges, ready for sealing and decoration.

User-Friendly Operation

PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for intuitive operation and real-time monitoring.

Easy adjustment for different tube sizes and material types.

Energy Efficiency

Low energy consumption with optimized extruder design.

Advanced motor systems reduce operational costs.

High Production Speed

Capable of producing hundreds of tubes per hour, depending on the material and size.

Production Workflow

Material Feeding

Raw plastic granules or laminated sheets are fed into the extruder.

Melting and Extrusion

The material is heated and pushed through the extrusion die to form the tube body.

Cooling

The extruded tube passes through a cooling system to solidify its shape.

Cutting and Trimming

The tube is cut to the desired length and edges are trimmed for a clean finish.

Preparation for Decoration

Tubes are prepared for additional processes, such as sealing, printing, and labeling.

Applications

The cosmetic tube extruder is used to produce packaging for:

Skincare Products: Creams, lotions, gels, and serums.

Haircare Products: Conditioners, masks, and styling gels.

Personal Care: Toothpastes, sunscreens, and hand sanitizers.

Benefits

Quality and Consistency: Ensures uniform and defect-free tubes for a premium look and feel.

Customization: Supports diverse tube designs and finishes to meet branding needs.

Efficiency: Reduces material waste and enhances production speed.

Durability: Produces tubes with strong structural integrity, ideal for handling and transportation.

Cost-Effective: Automated operation minimizes labor costs and maximizes output.

Customization Options

Tube diameter range (e.g., 13mm to 50mm).

Support for custom shapes and lengths.

Multi-layer extrusion for enhanced barrier properties.

Integration with printing and labeling systems.

Conclusion

The cosmetic tube extruder is a reliable, high-performance solution for producing premium-quality packaging for the cosmetic and personal care industry. With its ability to handle various materials and customization needs, it helps manufacturers create innovative, attractive, and functional packaging to meet market demands.

Custom-made filling, labeling and packing line

Whatever your business sector or product, Dachen provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking system.

Long-term use

Installation guided by our installation technical team

Guarantee 24-Hour Customer Service